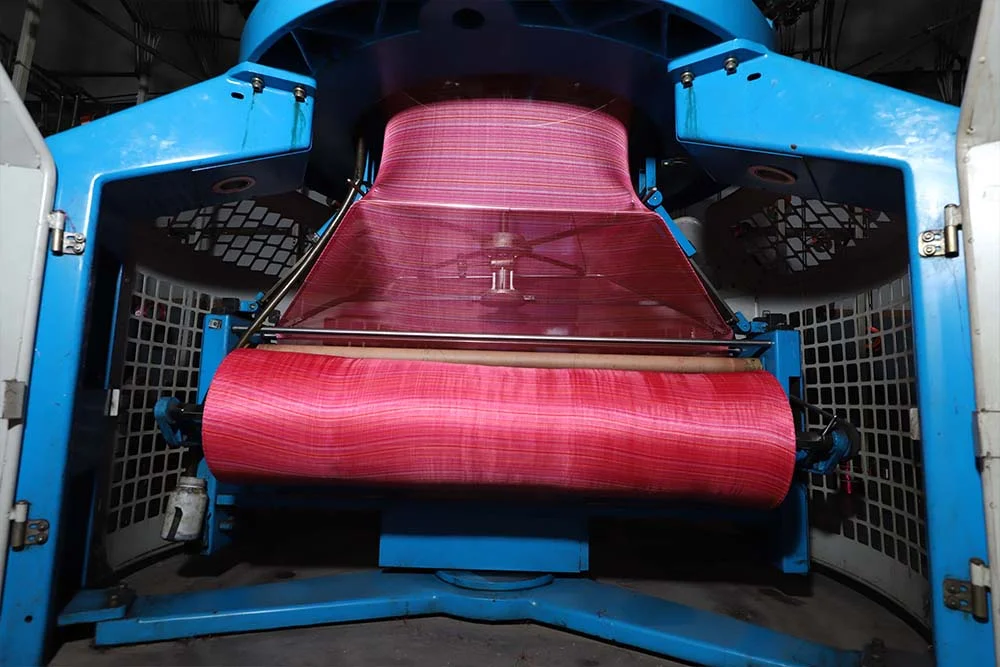

Infrastructure

- Home

- Infrastructure

CES

Central Engineering Services

takes care of uninterrupted supply of

- Raw water

- Soft and DM water

- Compressed air

- Chilled water

- Air conditioning for the process

- Treatment of the effluent

- Works on saving of energy and water conservation

- Maintain

CES can be regarded as the backbone for the entire plant and their responsibility is to maintain the plant and machinery in the top-class and in running condition 24x7x365. SDSPL has a team of experts and professionals (instrumentation, mechanical and electrical) in CES who have been responsible for several modifications and innovations carried out without interrupting the production in various plants.

Perfection

Quality Control

Polyester Chips:

SDSPL is equipped with latest equipment for analysis of polymers: G.C, U.V Spectro-photometer, Karl Fisher Auto-titrator etc. Regular quality checks are performed between every 4 hours of interval.

Fully Drawn Yarn:

SDSPL is equipped with latest equipment for analysis of Yarn to check the Elongation and Tenacity-Strength of the yarn (Statimat, Germany).

Spin Trak:

This equipment consists of variable zoom microscope to check each hole of spinneret accurately. One can inspect all types of capillary shapes such as circular, trilobal, octolobal, Star, etc., in real time.

HYPOX:

The HYPOX® unit is a safe, efficient, two step, hydrolysis based polymer to remove metal and ceramic parts alike from the process. The basis for the cleaning process is a. super-heated steam phase and b., an oxidation phase. After automatic inspection, data is stored for analysis using pictorial and graphical representations.

We have different equipment in the labs to check

- Microscope for checking filament cross section.

- Bursting Strength Tester for Packing Boxes

- Compression Strength Tester of Paper tube